BEISPIELE AUS DEM GUSSPROGRAMM FÜR OFENGUSS

ÖFEN, KAMINE, HEIZGERÄTE UND FEUERUNGSANLAGEN

ÖFEN, KAMINE, HEIZGERÄTE UND FEUERUNGSANLAGEN

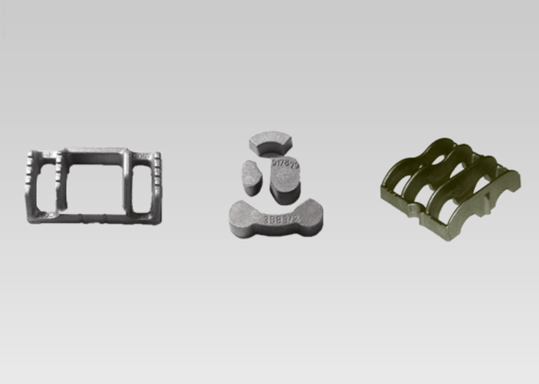

BEISPIELE AUS DEM GUSSPROGRAMM FÜR BESCHLÄGE

BESCHLÄGE UND OBERFLÄCHENTEILE

BESCHLÄGE UND OBERFLÄCHENTEILE

BEISPIELE AUS DEM GUSSPROGRAMM FÜR GETRIEBE

ANTRIEBSTECHNIK

ANTRIEBSTECHNIK

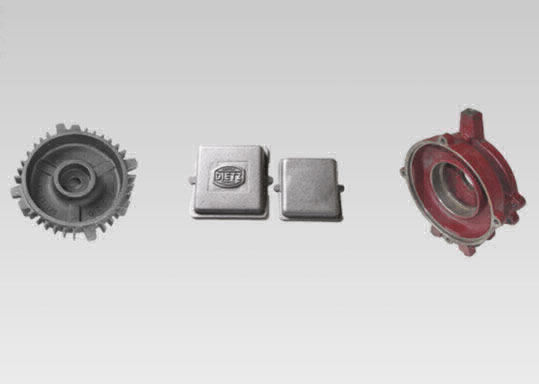

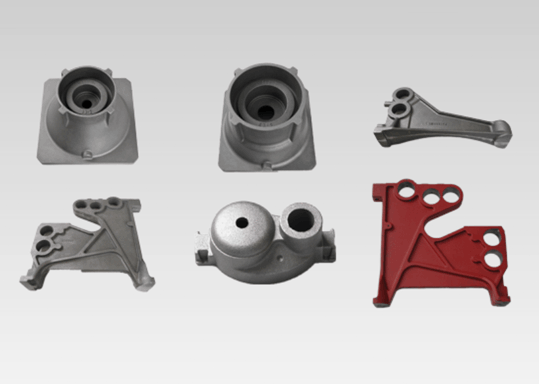

BEISPIELE AUS DEM GUSSPROGRAMM FÜR MOTOREN

ELEKTROMOTORENBAU

ELEKTROMOTORENBAU

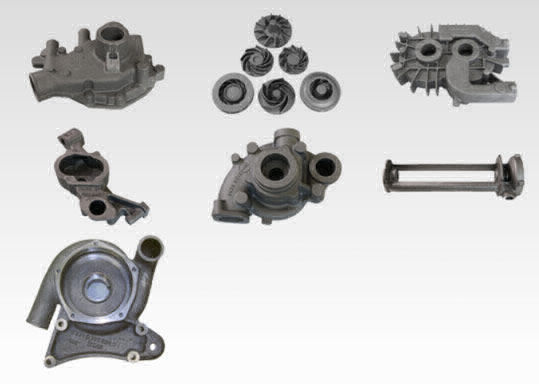

BEISPIELE AUS DEM GUSSPROGRAMM FÜR PUMPEN

PUMPENINDUSTRIE

PUMPENINDUSTRIE

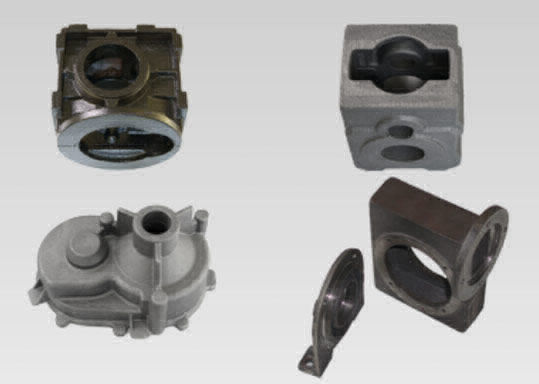

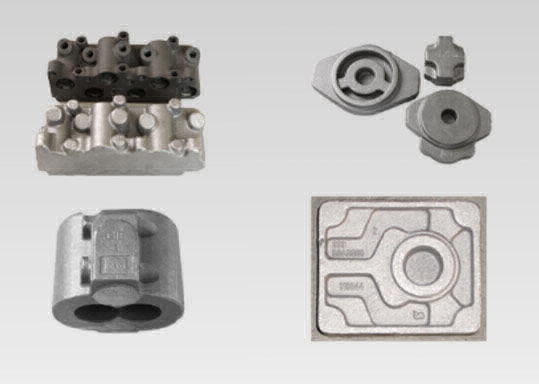

BEISPIELE AUS DEM GUSSPROGRAMM FÜR HYDRAULIK

KOMPONENTEN FÜR HYDRAULIKAGGREGATE

KOMPONENTEN FÜR HYDRAULIKAGGREGATE

BEISPIELE AUS DEM GUSSPROGRAMM FÜR KÜHLKOKILLEN

KÜHLEISEN UND KÜHLKOKILLEN

KÜHLEISEN UND KÜHLKOKILLEN

BEISPIELE AUS DEM GUSSPROGRAMM FÜR MASCHINENBAU

ALLGEMEINER MASCHINENBAU

ALLGEMEINER MASCHINENBAU

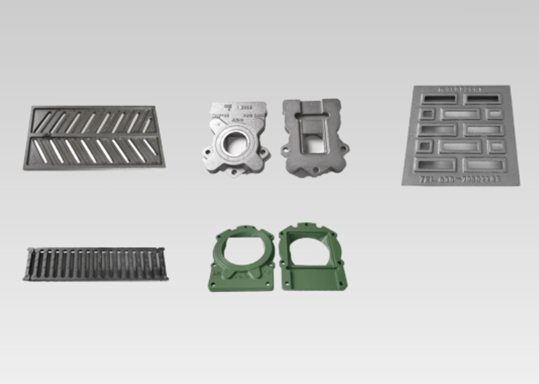

BEISPIELE AUS DEM GUSSPROGRAMM FÜR KANALISATION

ABSPERRSCHIEBER FÜR ABWASSERKANÄLE

ABSPERRSCHIEBER FÜR ABWASSERKANÄLE

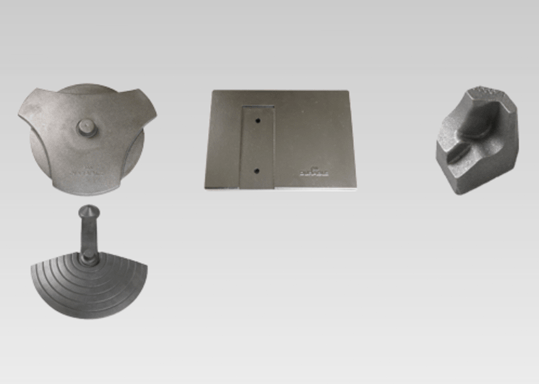

BEISPIELE AUS DEM GUSSPROGRAMM FÜR BESCHWERUNGEN

BALLASTE, BESCHWERUNGEN

BALLASTE, BESCHWERUNGEN